On this page, you can find info on:

- HybSi® licenses

- Membrane testing and process simulation

- Test equipment at TNO

Licenses and patents or interested in fabrication and marketing of HybSi®?

The HybSi® membrane and the necessary sealing and module technology are covered by a number of TNO patents. TNO is looking for interested parties (membrane manufacturers and system integrators) to take a license on its technology and broad patent portfolio. Potentially interested parties include companies that are interested in membrane fabrication, or that are interested in marketing full separation equipment that contain HybSi® membrane technology, or that are interested in the final utilization of it. We can provide a detailed technology transfer and aim for a joined effort in the further scale-up and market development of HybSi® membranes.

TNO is the best partner for scaling up HybSi® membrane technology for commercialization, both in membrane fabrication and in separation and test equipment that contain HybSi® (or other) membrane technology. Standard HybSi® pervaporation membranes for dehydration of organics liquids or the removal of methanol from organic liquids are available at TNO on lab and pilot scale (up to a few m2 of membrane area). TNO has licensed the HybSi® membrane technology to a membrane producer and these membranes including installations are now commercially available at Pervatech (NL). New innovative HybSi® membrane variances are available for testing on lab and pilot scale. The extensive know-how including the availability of test installations and modeling tools (e.g. Aspen simulation and process design) make TNO the ideal partner for developing innovative membrane separation systems.

Earlier licenses for the commercialisation of the HybSi® membrane technology from TNO have been granted to our partners:

– Pervatech, the Netherlands: https://pervatech.com/

When you are interested in also obtaining a license or for more information please contact us.

HybSi® in your own process, process simulation or pervaporation calculation tools?

TNO can provide and help you with all the technical knowledge in order to implement HybSi in your specific organic solvent separation process.

In close collaboration, TNO can assess the suitability of HybSi® membranes for your specific separation process and confirm this by lab scale (See below) and pilot scale tests. We can perform excellent dehydration or methanol removal tests under realistic conditions. Moreover, our wide expertise and experience makes us capable of designing the most suitable process, which will be evaluated by e.g. Excel calculations or Aspen flow sheeting including cost calculations. TNO can analyze the techno-economic viability of implementing HybSi® membranes in your process: a techno-economic feasibility study will give details of the impact on capital expenses, operating costs and benefits and a calculation of the investments needed. TNO has developed a calculation tool for pervaporation membranes that can be used for process evaluation and flowsheeting. The tool is an add-in to Aspen Plus and can be used for e.g. sensitivity and process optimization studies. Some details can be found here or pick up the Pervatool download.

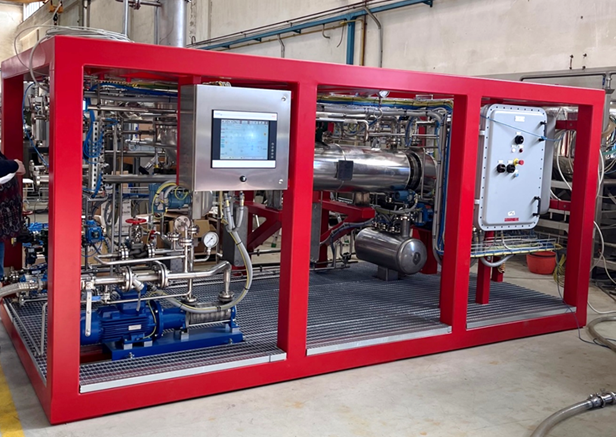

Pilot-scale demonstration of HybSi® membrane technology

After this a Go-NoGo decision will be made and when positively decided, an on-site pilot test would be a logic continuation. For this purpose, TNO has a newly build pilot-scale skid unit. This unit is able to run batch-wise as standalone equipment or in-line using a continuous feed. These tests would allow for an unambiguous assessment of the value of the HybSi® membrane system in your process.

To know more, visit Pilot-Scale Molecular Separation Unit.

If your are interested in a collaboration with TNO in order to make your separation processes more efficient, please contact us.

Want to do the tests yourself?

TNO provides to selected end-users two different single tube modules with HybSi® membrane. The first contains a membrane of ~40 cm2 and the second ~400 cm2. For more details and/or a price quotation please contact us. Download module information.

You can also hire the pilot scale test installation (coming up!).

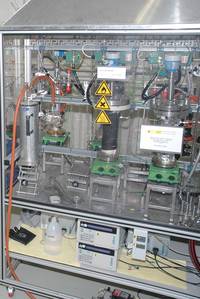

Laboratory measurements

TNO offers to perform pervaporation measurements for interested end-users on their industrial mixtures. The emphasis is on water and methanol separation from organic solvents. To this end, TNO has multiple glass pervaporation set-ups available. For more demanding conditions 5 stainless steel autoclaves are available that can run up to 30 bars pressure and 200 °C in a batch experiment set-up. These installations can run 24/7 including fresh feed addition. They are normally operated with one membrane of ~15 cm length and typically use 1-2 liter of feed liquid. For larger scale measurements with continuous flow feed conditions a set-up with a feed capacity of ~35 liters is available. This set-up can be run with six membranes in series with pressures up to 25 bars and temperature up to 150 °C.

TNO also owns a new lab-scale installation that can operate in both pervaporation and vapor permeation modes in cross-flow configuration. This installation is equipped with a pump circulating the feed mixture around the membrane module in a cross-flow configuration and can operate up to 150 °C.

Related laboratory equipment

– Permporometer: Knowing the pore size and size distribution of selective layers is essential in the development and application of ceramic membranes. The TNO Permporometer offers a quick, cheap and effective method for the characterization of micro- and mesoporous membranes. The Permporometer has been developed by the Energy research Centre of the Netherlands (ECN, now TNO), and has been proven to be essential in the successful development of novel ceramic membranes.

– GPI: Knowing the permeance characteristics of selective layers is essential in the development and application of porous and dense membranes for gas separation applications. The TNO Gas Permeance Installation (GPI) offers a quick, cheap and effective method for the characterization of these types of membranes. The GPI has been developed by the Energy research Centre of the Netherlands and has been proven to be essential in the successful development of porous and dense membranes.