HybSi® is the trade name of a nonporous membrane system with an unprecedented high stability under both hydrothermal and acidic conditions, that can be used for efficient pervaporation and vapor permeation.

On this page, you will get answer to the following questions:

- What makes the HybSi® membrane revolutionary?

- What are the possibilities for your company with HybSi®?

HybSi®: a revolutionary pervaporation membrane

As can be read on the information page about pervaporation processes, pervaporation offers a lot of advantages to traditional separation processes. Yet, the currently available polymer and ceramic pervaporation membranes have some shortcomings.

The HybSi® team has been working over the years to overcome and remove the limitations of these currently available pervaporation membranes by designing a revolutionary system that can be applied in a much wider application window. The result of all this work is the development of a organic-inorganic hybrid membrane, the HybSi® membrane.

HybSi® is stable in water at high temperatures, in (a)protic solvents, and in the presence of acids. The application window of pervaporation membranes is expanded with separation processes in reactors, aggressive feeds and at high temperature. The membrane has survived a number of extended tests (up to 3 years) under demanding conditions (at 150 °C), see our publications.

In short, HybSi® membranes offer the following advantages:

- Energy savings of up to 50%

- Azeotrope separation

- Decrease usage of cooling water

- Enhanced product quality also through milder conditions

- Reduced formation of side products

- Higher plant availability

- Chemical resistant

- Stable up to high temperatures

- Continuous process

Material details

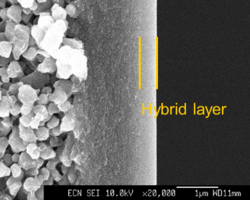

HybSi® is an organic-inorganic hybrid silica-based amorphous material. The hybrid nature of this material lies in the fact that each silicon atom is not only connected to oxygen atoms as in pure silica, but also to an organic fragment. The special feature of HybSi® is that the organic fragments are acting as integral bridging fragments of the structure, and not just as end standing groups as in methylated silica. The result is a true hybrid silica pore network in which organic and inorganic fragments cooperate. It is prepared by a sol-gel process from so-called bis-silyl precursors, such as BTESM ((EtO)3Si–CH2–Si(OEt)3) and BTESE ((EtO)3Si–CH2CH2–Si(OEt)3).

Several explanations have been proposed for the remarkable stability of the HybSi®. These include:

– More stable bonds: the hydrothermally instable Si-O-Si bonds are replaced by Si-(CH2)n-Si bonds

– Higher crack propagation energy resulting in more ductile material in which initiated nano-cracks do not easily grow to a defect

– Increased connectivity number of the basic building block from four to six siloxane bridges, resulting in a lower surface diffusion coefficient

– Lower solubility, the larger bis-silyl units are expected to have a much lower solubility leading to suppressed mobility of silica fragments.

More detailed technical information about HybSi® can be found in our publications.

HybSi® in your process

In close collaboration with the client TNO can assess the suitability of HybSi® membranes for your specific separation process and confirm this by small scale lab tests. The applicability of HybSi® membrane in a number of dehydration processes of organic solvents has already been proven. Examples of water and methanol azeotropes that can be separated with the HybSi® membrane system include:

| Permeating species | Retained species | Azeotrope (wt% of retained species) |

Water | Acetonitrile | 83.7 |

| Water | Ethanol | 95.5 |

| Water | n-Propanol | 71.7 |

| Water | t-Butanol | 88.3 |

| Water | Ethylene chloride | 91.8 |

| Water | Methyl acetate | 95.0 |

| Water | Methyl ethylketone | 89.0 |

| Water | Tetrahydrofuran | 95.0 |

| Methanol | Toluene | 31.0 |

| Methanol | Methyl acetate | 81.3 |

| Methanol | Tetrahydrofuran | 69.0 |

Other dewatering examples for which HybSi® can be used include complex distillations and processes like:

– Acetone/phenol in e.g. the oxidation of. cumene

– Acrylates

– Bisphenol A

– Carbonates

– Diols

– EDC/VCM/PVC

– Isocyanates

– Propylene oxide

– Terephthalate compounds and terephthalic acid

The extensive know-how of TNO has lead to several patents on the HybSi® membranes, on a module concept and a membrane sealing concept. Standard HybSi pervaporation membranes for dehydration of organic liquids are available at TNO on lab scale and licensees offer the membranes commercially.

What to know more about the HybSi product and service possibilities for your process or are you interested in membrane fabrication or marketing, please contact us.